- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

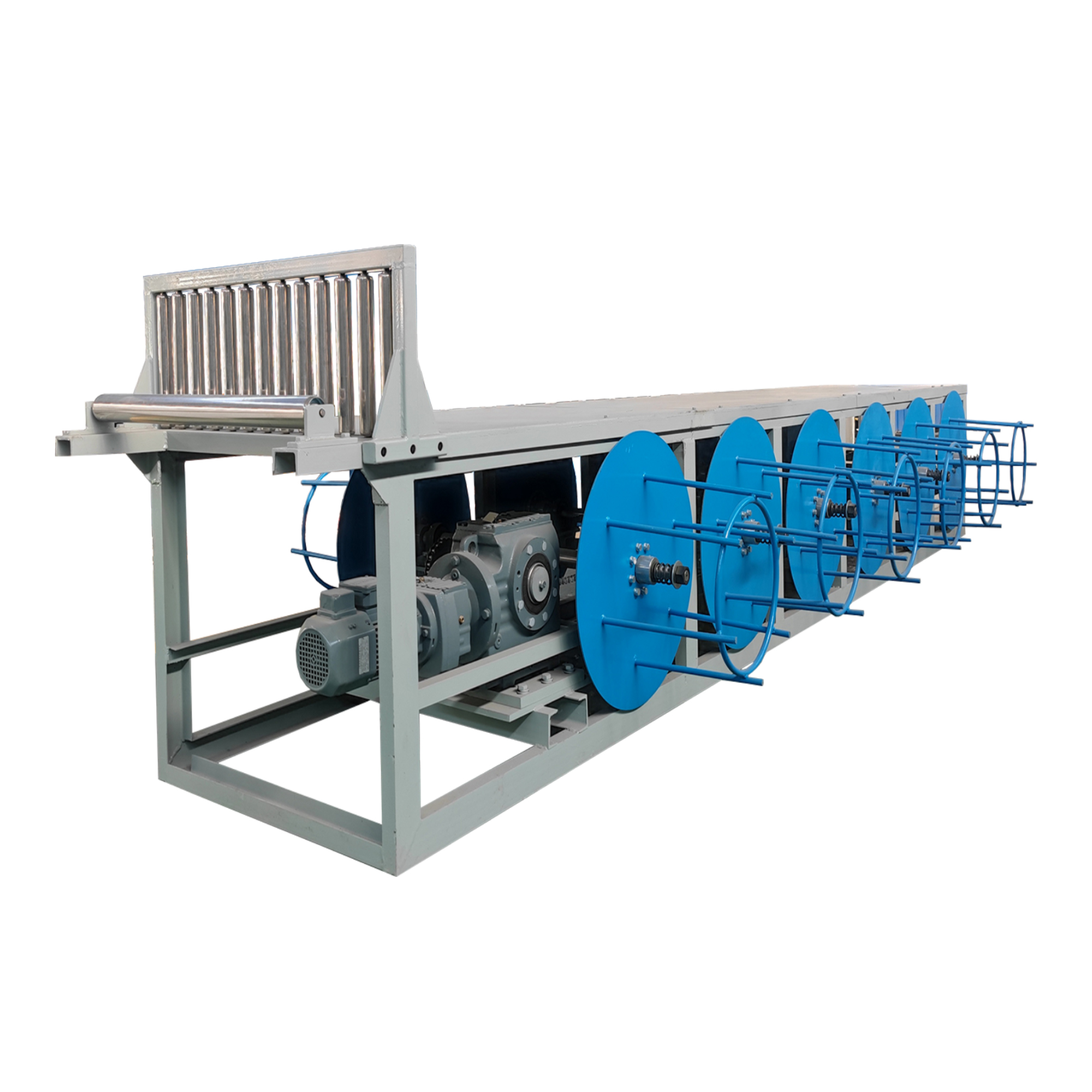

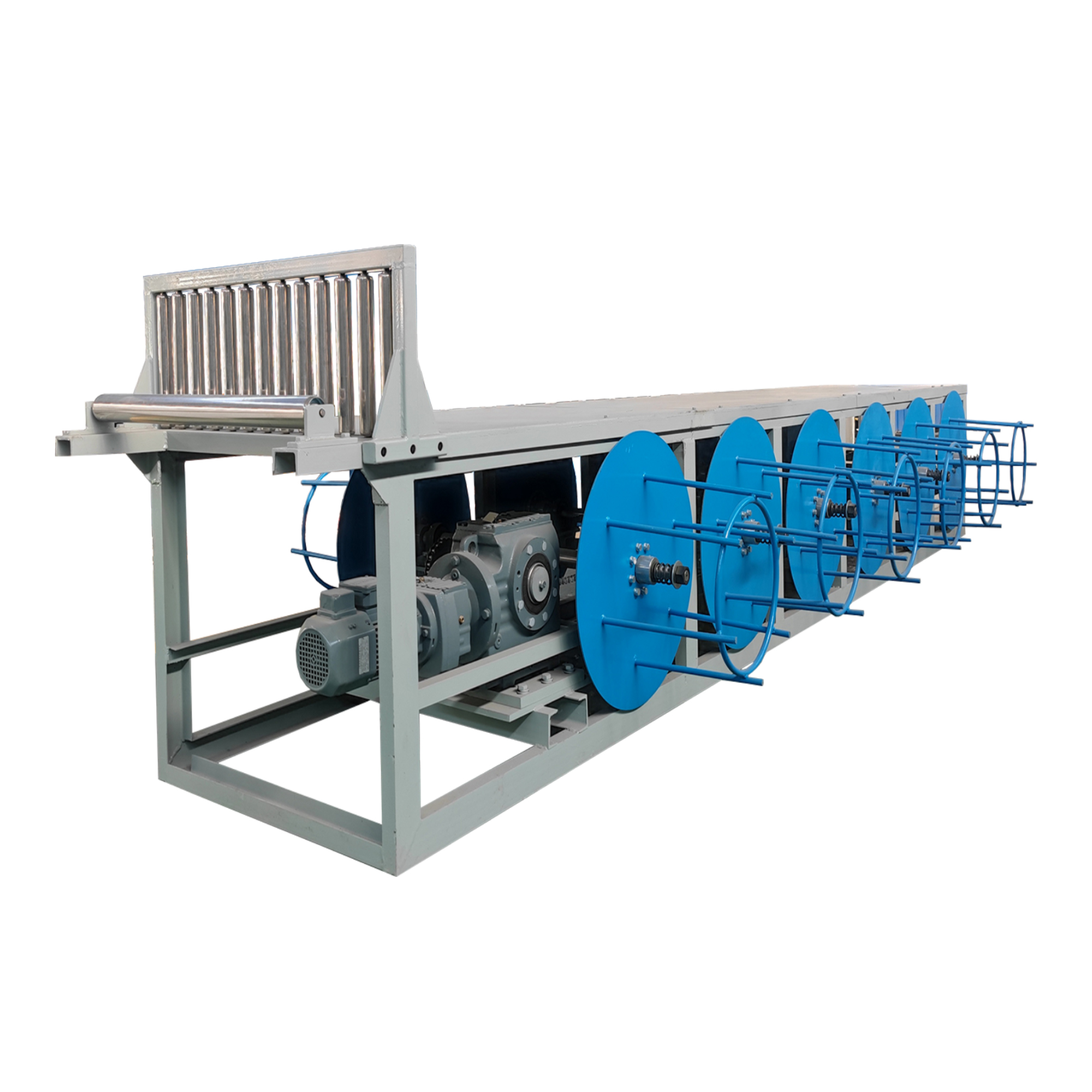

Application:

Horizontal Continuous Casting Machine is a production lines for producing the rod, tube, bar, plate, billet, wire, strip of copper/Aluminum or other metals. And This production lines are widely service for the industries like produce the electric wire, cable, electron, lock making, water heating equipments, refrigeration .

| Item | Horizontal continuous casting machine | |

| Output | Customized | |

| Holding furnace | Induction furnace or resistance furnace | |

| Furnace body capacity | 100KG-6Ton | |

| Casting Metal | High temperature alloy (iron-base alloy, nickel-based alloy, cobalt-base alloys) Nonferrous metals (copper, aluminum, zinc, tin, silver, gold) Ferrous alloys (steel, iron) |

|

| Type | Horizontal type | |

| Power supply | Electric | |

| Power | Customized | |

| Crystallizer | Designed by different metal | |

| Strands | Customized | |

| Drawing Speed | 50mm-800mm/min | |

| Available casting billet | Tube / Round bar / Square / Strip | |

| Reference Picture |  |

|

Don’t hesitate to fill in the form & we will reply to you as soon as possible!