- ADD: Luo Yang City, He Nan Province

- Whatsapp/Wechat: 8617796741029

- Email: zhang@wanf-furnace.com

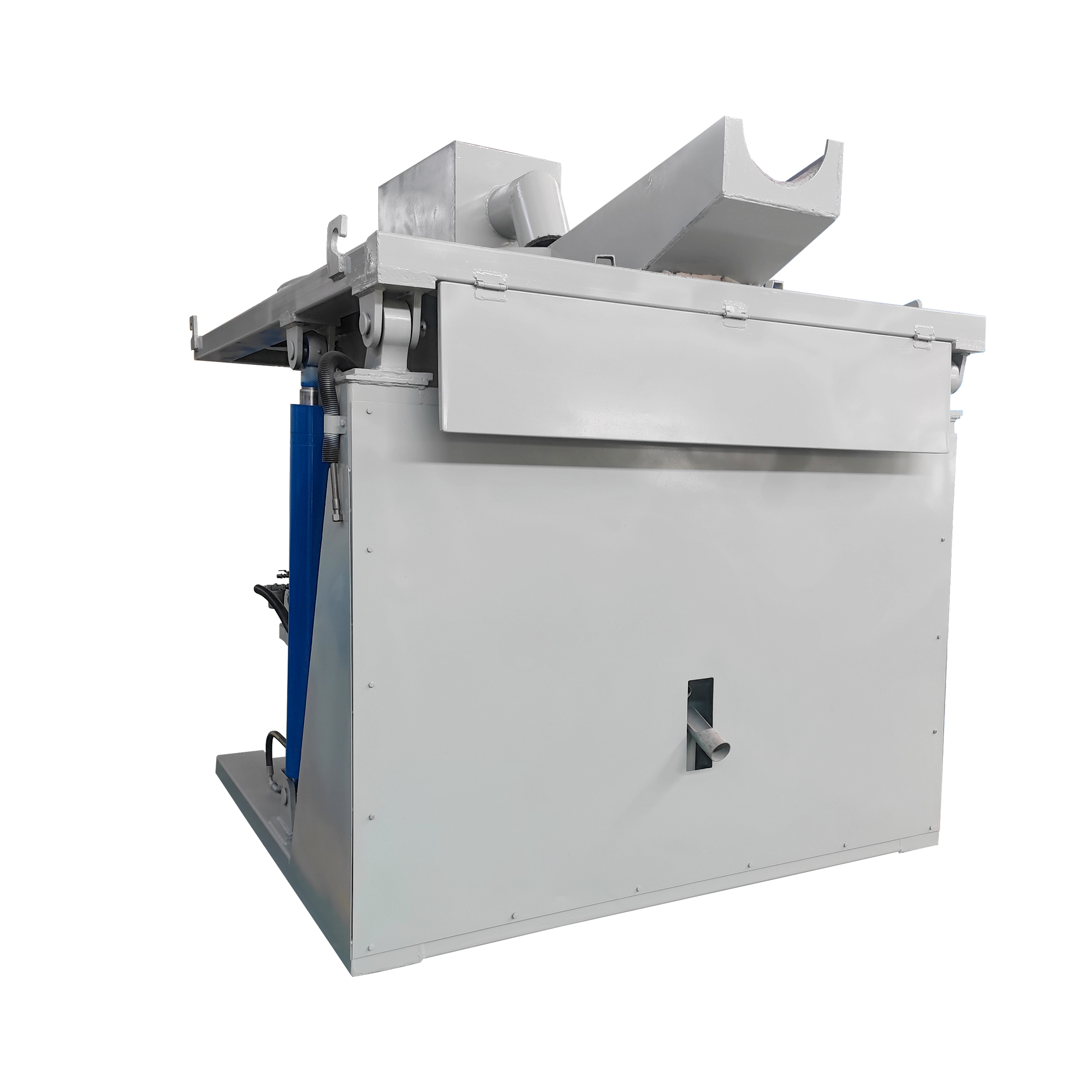

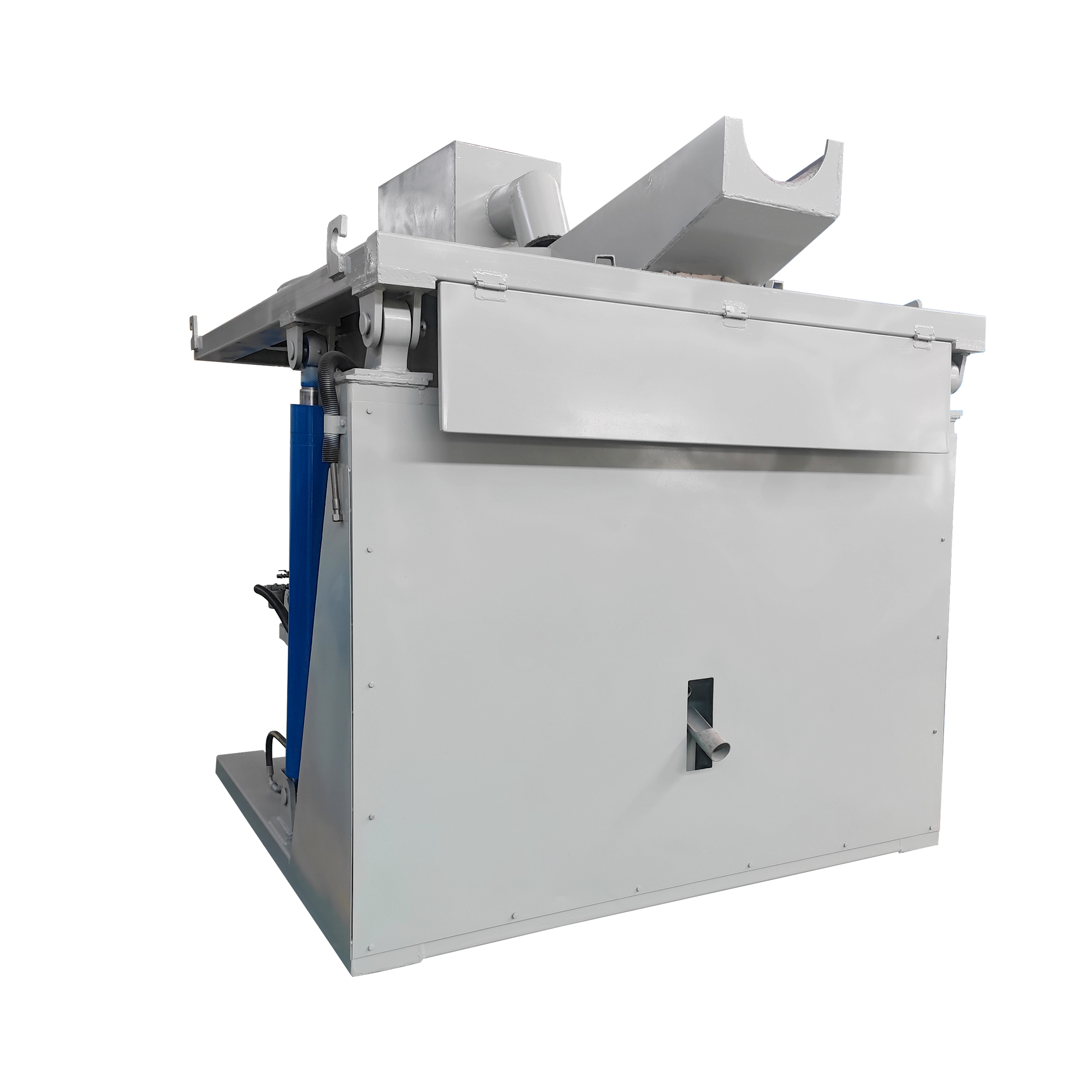

Product overview:

A fuel/gas melting furnace is an industrial melting equipment that uses diesel, heavy oil, or gas as energy sources. It is widely used in the melting, casting, and alloy preparation of metals such as aluminum, zinc, and lead< br /> Adopting advanced combustion technology and heat exchange design to achieve high thermal efficiency, low energy consumption, and stable temperature control. Adopting advanced combustion technology and heat exchange design to achieve high thermal efficiency, low energy consumption, and stable temperature control。.

| 型号 | WFR-500 | WFR-600 | WFR-800 | WFR-1000 | WFR-1250 | WFR-1500 |

| 坩埚容量 | 500Kg | 600Kg | 800Kg | 1000Kg | 1250Kg | 1500Kg |

| 熔化速度 | 100-120Kg/H | 120-150Kg/H | 150-200Kg/H | 270Kg/H | 360Kg/H | 430Kg/H |

| 坩埚尺寸 | φ880*680mm | φ880*750mm | φ1040*750mm | φ1040*830mm | φ1040*1040mm | φ1040*1200mm |

Don’t hesitate to fill in the form & we will reply to you as soon as possible!